Hey Guys/Gals…. Sorry I haven’t been posting much this summer with the heat, the day job and trying to spend as much time with my son as possible this summer it’s been a little lacking in the woodworking and blogging department. I will be back at it more when the weather starts to cool off. In the meantime my Dad built an amazing Pie Safe for my sister and did a write up/story on it and I wanted to publish it for him. I hope you like it. I have a feeling I will be having him guest blog for me more so we can bring you additional content over the months.

--Grover

It’s funny how things sometimes happen. A couple months ago, Grover decided he was going to build a Jelly Cupboard (Grover is my son). Well about that time, my daughter, who works for a public library, decided she would like to have a pie safe. I thought that would be a good project, so I told her to find the plan she liked and I would give it a try. So a few days later she brought home from the library a New Yankee Workshop plan book written by Norm Abrams. I looked at the plan and thought, this could be more than I could handle. Dado’s, biscuit joinery, and so on, seemed a little much.

Well, Grover started building the jelly cupboard. We discussed the pie safe, and before I could say, “Table saw dado blade” three times, he had ordered the plan from the New Yankee Workshop, and had bought a great set of Freud dado blades. Next thing I knew I was being instructed on the use of a dado blade setup and Kreg pocket hole jig. He handed me a set of plans and a video on how to build the pie safe and said “No excuses, build it.”

Grover patiently explained to his “old dad” that it would be easy. Since he was building the jelly cupboard, it was the perfect time to explain the similarities in the two projects. Dado’s, pocket hole joints, and door construction. So, I brought the plans, video, and dado blade back to my shop. There they set for a couple of weeks, until my daughter asked “How’s the pie safe coming? Uh, Uh, well I gotta get the wood, then I can get started. Next thing I knew, we were at the home improvement store, with cut list in hand. Loaded the truck with the need lumber and back to the shop we go. A few days later, I made the first cut, then the second. “Hey this ain’t so bad.” Guess Grover, was right, this is easy. Then it happened. There’s and old saying, measure twice and cut once. Well, I read the other day a saying that more fits my situation. “Measure twice, cut once, scream loudly, reach for another board.” But I guess that’s why you buy a few extra boards.

Grover patiently explained to his “old dad” that it would be easy. Since he was building the jelly cupboard, it was the perfect time to explain the similarities in the two projects. Dado’s, pocket hole joints, and door construction. So, I brought the plans, video, and dado blade back to my shop. There they set for a couple of weeks, until my daughter asked “How’s the pie safe coming? Uh, Uh, well I gotta get the wood, then I can get started. Next thing I knew, we were at the home improvement store, with cut list in hand. Loaded the truck with the need lumber and back to the shop we go. A few days later, I made the first cut, then the second. “Hey this ain’t so bad.” Guess Grover, was right, this is easy. Then it happened. There’s and old saying, measure twice and cut once. Well, I read the other day a saying that more fits my situation. “Measure twice, cut once, scream loudly, reach for another board.” But I guess that’s why you buy a few extra boards.

Woodworking is suppose to be a learning experience. Anyway, since this is turning into a family project, my daughter, had at this point, seen the progress and said she would like to help. She wanted to punch the tin that would go in the doors. No problem, first find the pattern you want, second find a supplier for the

Woodworking is suppose to be a learning experience. Anyway, since this is turning into a family project, my daughter, had at this point, seen the progress and said she would like to help. She wanted to punch the tin that would go in the doors. No problem, first find the pattern you want, second find a supplier for the tin, third order it, and fourth build the jig that will be needed to hold the tin so it can be punched. Well, she got the pattern, found a supplier for the tin, and even ordered it. I didn’t really think she would build the holding jig for the tin, so since it was only a 20 minute project, I made the jig. I told her 3 out of 4 wasn’t bad. That’s when she informed me she got three out of three, said she never intended to build a jig. “Would you be interested in punching the 6 panels of tin that will be needed to complete the project.” She said “sure” and started on the first one. Well, you know a big hammer and a punch can really work on the wrists. So the next day after completing one panel, her wrist were so sore, I like a good dad said, “Hey, that’s gotta be rough on your arms, let me do the next one. Ooops, before the day way done, I had finished the next 5.

tin, third order it, and fourth build the jig that will be needed to hold the tin so it can be punched. Well, she got the pattern, found a supplier for the tin, and even ordered it. I didn’t really think she would build the holding jig for the tin, so since it was only a 20 minute project, I made the jig. I told her 3 out of 4 wasn’t bad. That’s when she informed me she got three out of three, said she never intended to build a jig. “Would you be interested in punching the 6 panels of tin that will be needed to complete the project.” She said “sure” and started on the first one. Well, you know a big hammer and a punch can really work on the wrists. So the next day after completing one panel, her wrist were so sore, I like a good dad said, “Hey, that’s gotta be rough on your arms, let me do the next one. Ooops, before the day way done, I had finished the next 5.

Well, all during this time, I would go to my son’s shop and and get a few hints, watching the progress on his jelly cupboard. I even l

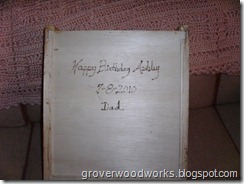

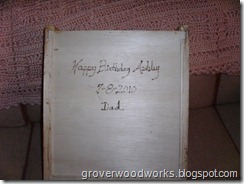

Well, all during this time, I would go to my son’s shop and and get a few hints, watching the progress on his jelly cupboard. I even l iked the Kreg Pocket Hole Jig so much I bought one. The plan called for biscuit joinery, but the pocket holes seemed to be much simpler. In hind sight, either would have been simple. Grover also taught me how to use a biscuit joiner. It’s very humbling to have your son teach you, after a lifetime of teaching him. But he made me feel better about the situation, when he said my four year old grandson (Grover Jr.) came in the shop a few days before and corrected him on a woodworking project he was working on. Now that’s humbling. So the pie safe started to take shape. I ordered a small plaque that said “Happy Birthday” and wood burned an inscription on the bottom of one of the drawers. Anyway attached are some of the pictures of the pie safe progress and also a finished picture sitting in the house. Hope it will inspire many of you to give something like this a try.

iked the Kreg Pocket Hole Jig so much I bought one. The plan called for biscuit joinery, but the pocket holes seemed to be much simpler. In hind sight, either would have been simple. Grover also taught me how to use a biscuit joiner. It’s very humbling to have your son teach you, after a lifetime of teaching him. But he made me feel better about the situation, when he said my four year old grandson (Grover Jr.) came in the shop a few days before and corrected him on a woodworking project he was working on. Now that’s humbling. So the pie safe started to take shape. I ordered a small plaque that said “Happy Birthday” and wood burned an inscription on the bottom of one of the drawers. Anyway attached are some of the pictures of the pie safe progress and also a finished picture sitting in the house. Hope it will inspire many of you to give something like this a try.

“Happy Woodworking”

Grover’s Dad.